About us

Welcome to iStar !

iStar founded in 2011, is a national high-tech innovation enterprise focusing on the R&D, design, and production of video game accessories. Our cores: Innovation and quality. The experienced team continues to develop game accessories for Switch, PS, PC, Xbox and mobile phone games. All products are private models and have appearance patent certificates.

After years of hard work, iStar is over 10,000 ㎡ and has more than 300 employees. An experienced R&D team provides one-stop services, from ID design, mold design, SMT, shell injection molding , LOGO silk screen printing, and product assembly and packaging, give us your idea just and we will help you realize it perfectly.

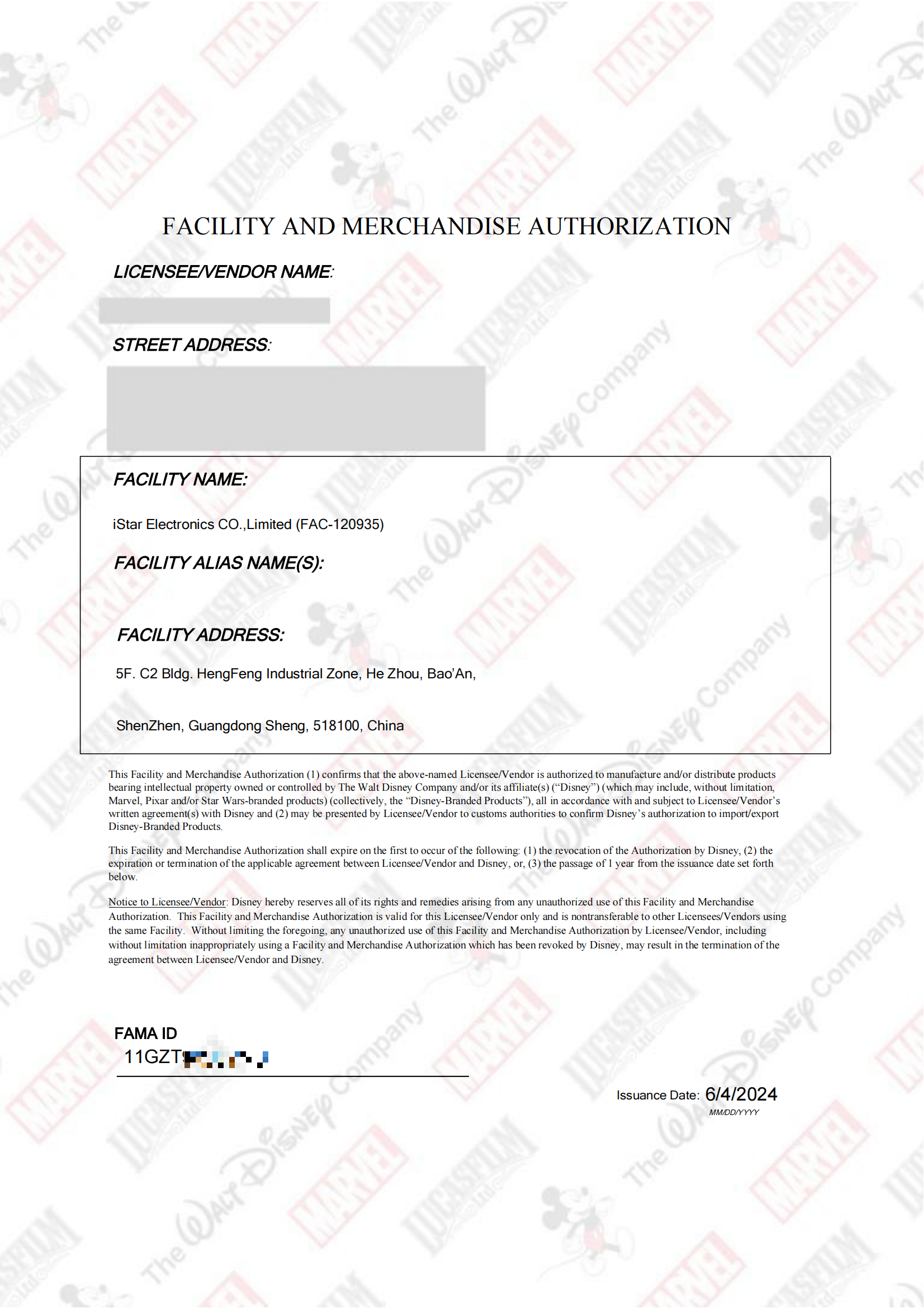

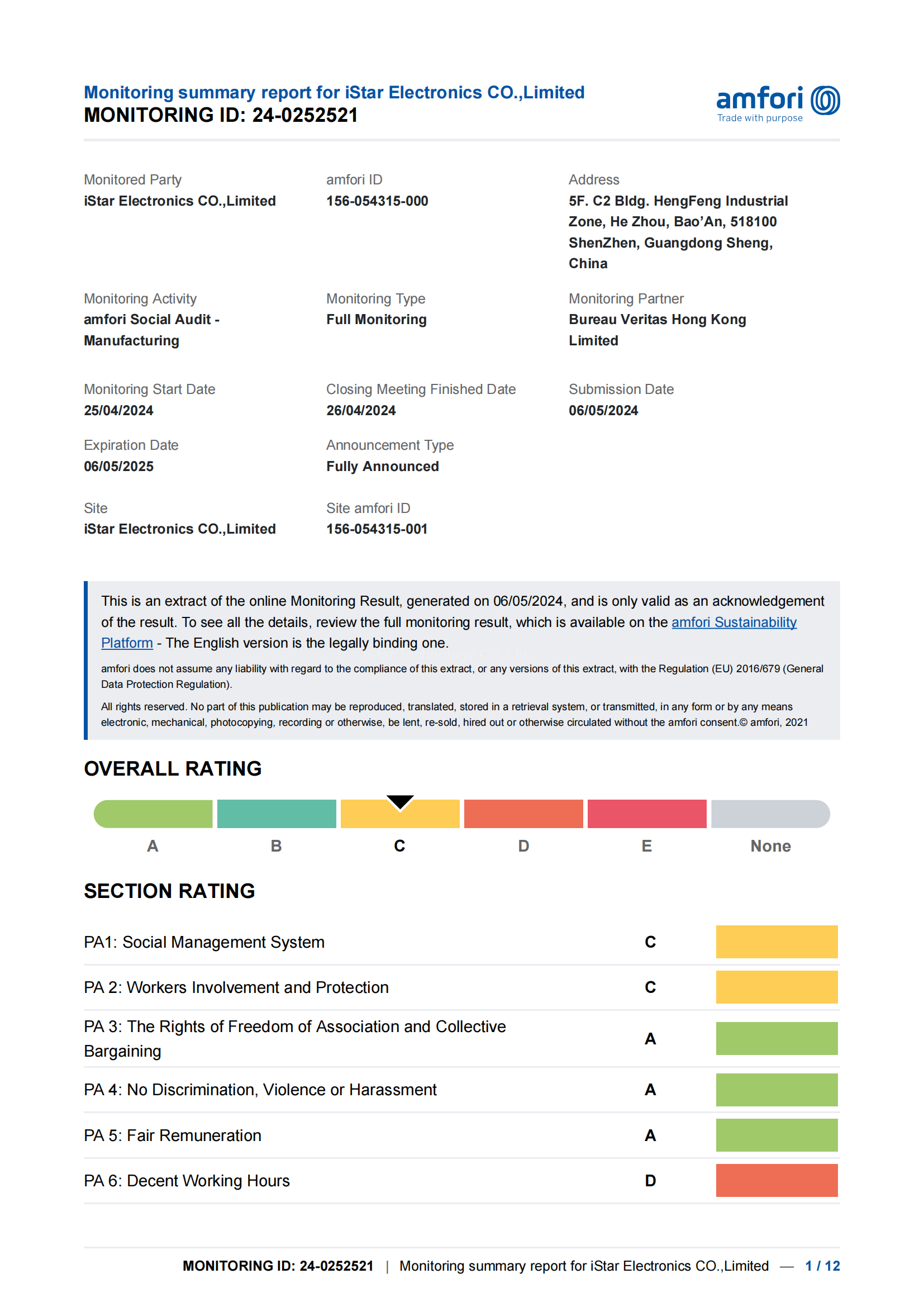

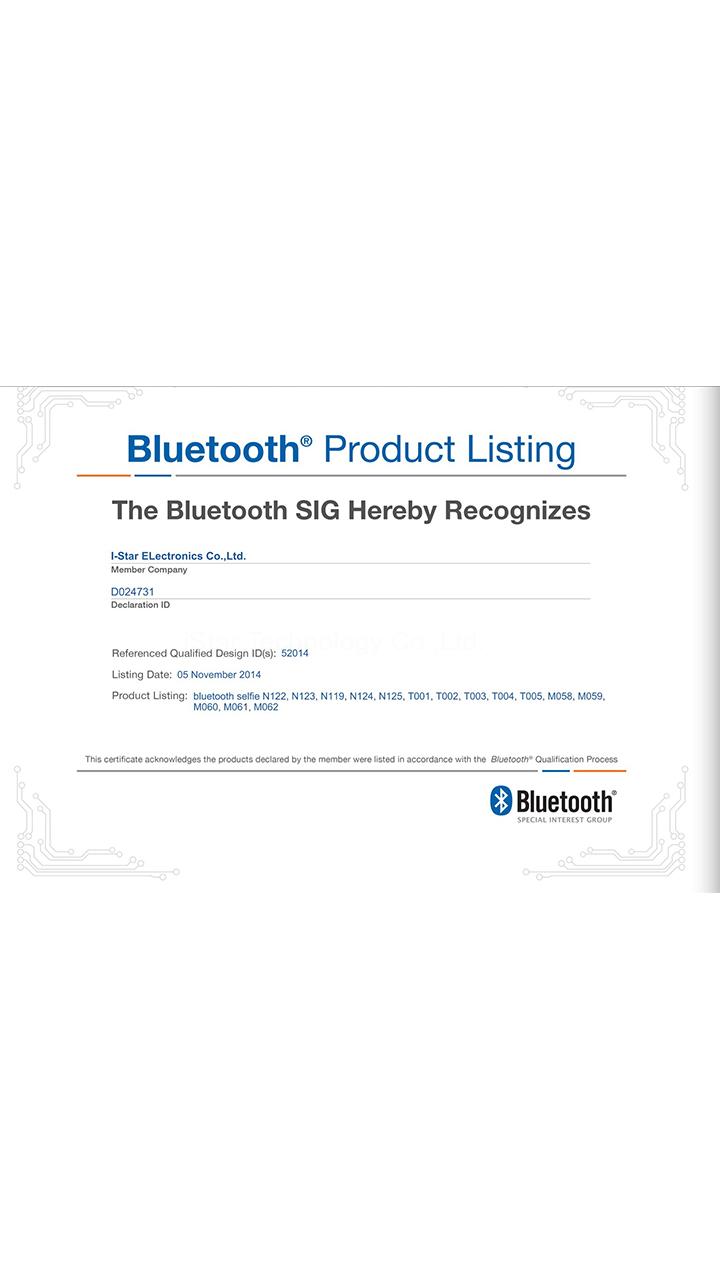

In 2023, iStar got the title of high-tech enterprise. Now our products are exported to Europe, America, Japan, South Korea, and Southeast Asia. It is a member of Apple MFI & Bluetooth BQB; BSCI, Disney audit factory!

Choose iStar, Trust iStar, Order welcome!

Our Certifications

Our Patents

Department Introduction

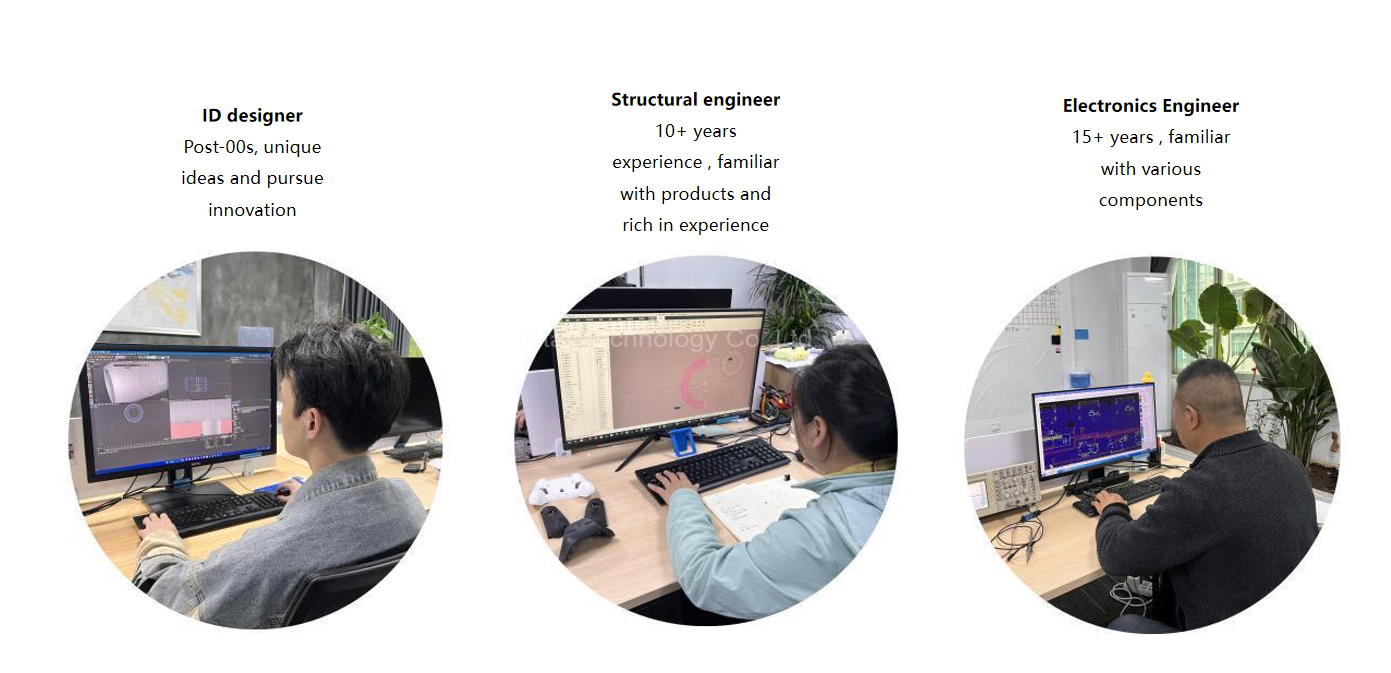

1. R&D team

There are many experienced ID designers, structural engineers, and electronic engineers.

Able to efficiently help customers realize their ideas and complete ODM & OEM orders

There are 2 advanced SMT production lines, introduced Yamaha machines imported from Japan,

and adopted automatic optical inspection products to ensure that PCBA is completed more efficiently.

3. Mold Workshop

In order to provide customers with better services and shorten the new product cycle, we set up an independent mold department, multiple professional equipment imported from Japan. CNC, CNC milling machines, spark machines, slow wire cutting machines, etc., and experienced machine tool operators, processing in strict accordance with the drawing requirements to ensure the manufacturing quality and accuracy of the mold.

A total of 17 injection machines, including 6 double-shot injection machines.

From feeding, injection molding, and discharging, all are intelligently controlled to ensure efficient and high-quality product production.

5. IMD Workshop

Any pattern can be designed, using advanced in-mold injection technology, with a low defect rate, and production can be completed with high quality and timeliness.

6. Reliability Testing Device

With Joystick Using Life, Plug Force Test Machine, Salt Spray Test Chamber etc., device.

7. Assemble Workshop

Four Production Lines, and the capacity is 300k pcs each month.

Contact us for OEM/ODM orders!